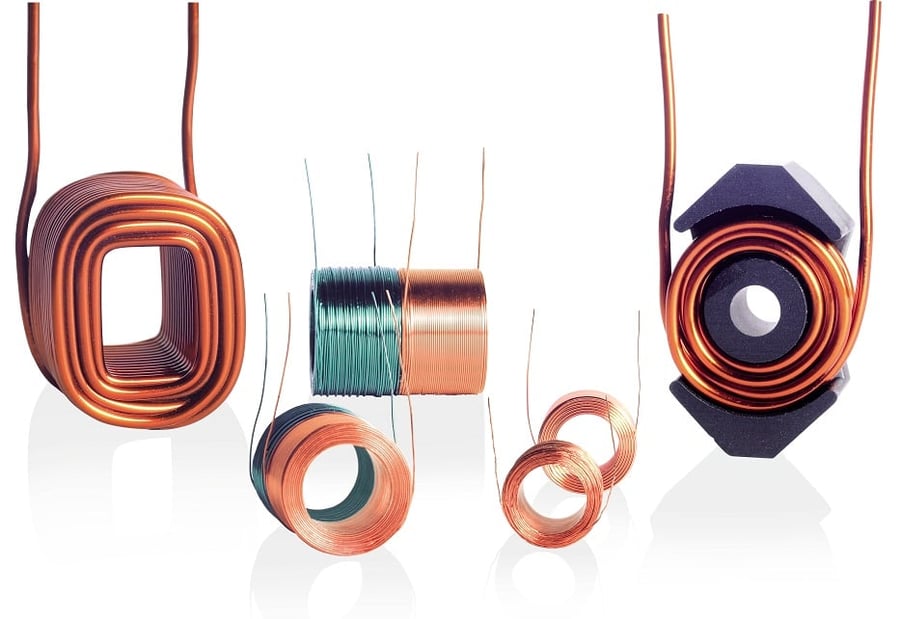

MICRO COILS (AIR CORE) AT A GLANCE

The versatility and impressive performance of micro coils with air core make them a top choice among medical and sensor technology engineers. When selecting a wire for these coils, the smallest option available is 0.020 mm, ensuring excellent conductivity and minimal resistance for enhanced efficiency. Micro coils with air core are available in various sizes, allowing for customization based on specific requirements. The choice of conductor material is crucial in determining overall performance, with copper being widely preferred for its high electrical conductivity and superior efficiency. Design tips for these coils include ensuring proper insulation to prevent short circuits and optimizing the number of turns to achieve the desired inductance. Additionally, it is important to consider connection options early on, as this can be as challenging as working with the ultra-thin wire. By considering these important factors, engineers can create micro coils with air core that deliver exceptional performance and meet their needs for medical devices.

/Micro%20coil%20air%20core%201.png?upsize=true&upscale=true&width=570&height=500&name=Micro%20coil%20air%20core%201.png)

/Micro%20coil%20air%20core%202.png?upsize=true&upscale=true&width=570&height=500&name=Micro%20coil%20air%20core%202.png)

/Micro%20coil%20air%20core%207.png?upsize=true&upscale=true&width=570&height=500&name=Micro%20coil%20air%20core%207.png)

/Micro%20coil%20air%20core%208.png?upsize=true&upscale=true&width=570&height=500&name=Micro%20coil%20air%20core%208.png)

/Micro%20coil%20air%20core%205.png?upsize=true&upscale=true&width=570&height=500&name=Micro%20coil%20air%20core%205.png)

/Medizin_luftspule_08.png?upsize=true&upscale=true&width=570&height=500&name=Medizin_luftspule_08.png)

/Medizin_luftspule_05.png?upsize=true&upscale=true&width=570&height=500&name=Medizin_luftspule_05.png)

/Micro%20coil%20air%20core%209.png?upsize=true&upscale=true&width=570&height=500&name=Micro%20coil%20air%20core%209.png)

/Micro%20coil%20air%20core%204.png?upsize=true&upscale=true&width=570&height=500&name=Micro%20coil%20air%20core%204.png)

/Medizin_luftspule_07.png?upsize=true&upscale=true&width=570&height=500&name=Medizin_luftspule_07.png)

/Micro%20coil%20air%20core%203.png?upsize=true&upscale=true&width=570&height=500&name=Micro%20coil%20air%20core%203.png)

/Micro%20coil%20air%20core%206.png?upsize=true&upscale=true&width=570&height=500&name=Micro%20coil%20air%20core%206.png)

/Medizin_luftspule_02.png?upsize=true&upscale=true&width=570&height=500&name=Medizin_luftspule_02.png)

/Micro%20coil%20air%20core%201.png?upsize=true&upscale=true&width=100&height=87&name=Micro%20coil%20air%20core%201.png)

/Micro%20coil%20air%20core%202.png?upsize=true&upscale=true&width=100&height=87&name=Micro%20coil%20air%20core%202.png)

/Micro%20coil%20air%20core%207.png?upsize=true&upscale=true&width=100&height=87&name=Micro%20coil%20air%20core%207.png)

/Micro%20coil%20air%20core%208.png?upsize=true&upscale=true&width=100&height=87&name=Micro%20coil%20air%20core%208.png)

/Micro%20coil%20air%20core%205.png?upsize=true&upscale=true&width=100&height=87&name=Micro%20coil%20air%20core%205.png)

/Medizin_luftspule_08.png?upsize=true&upscale=true&width=100&height=87&name=Medizin_luftspule_08.png)

/Medizin_luftspule_05.png?upsize=true&upscale=true&width=100&height=87&name=Medizin_luftspule_05.png)

/Micro%20coil%20air%20core%209.png?upsize=true&upscale=true&width=100&height=87&name=Micro%20coil%20air%20core%209.png)

/Micro%20coil%20air%20core%204.png?upsize=true&upscale=true&width=100&height=87&name=Micro%20coil%20air%20core%204.png)

/Medizin_luftspule_07.png?upsize=true&upscale=true&width=100&height=87&name=Medizin_luftspule_07.png)

/Micro%20coil%20air%20core%203.png?upsize=true&upscale=true&width=100&height=87&name=Micro%20coil%20air%20core%203.png)

/Micro%20coil%20air%20core%206.png?upsize=true&upscale=true&width=100&height=87&name=Micro%20coil%20air%20core%206.png)

/Medizin_luftspule_02.png?upsize=true&upscale=true&width=100&height=87&name=Medizin_luftspule_02.png)

.png?upsize=true&upscale=true&width=72&height=72&name=settings(1).png)